Fly ash, a waste product of coal-based electricity generation, has been a major problem in the U.S. and a widespread waste management issue. More than 50 percent of fly ash can end up in landfills, subsequently affecting nearby environments.

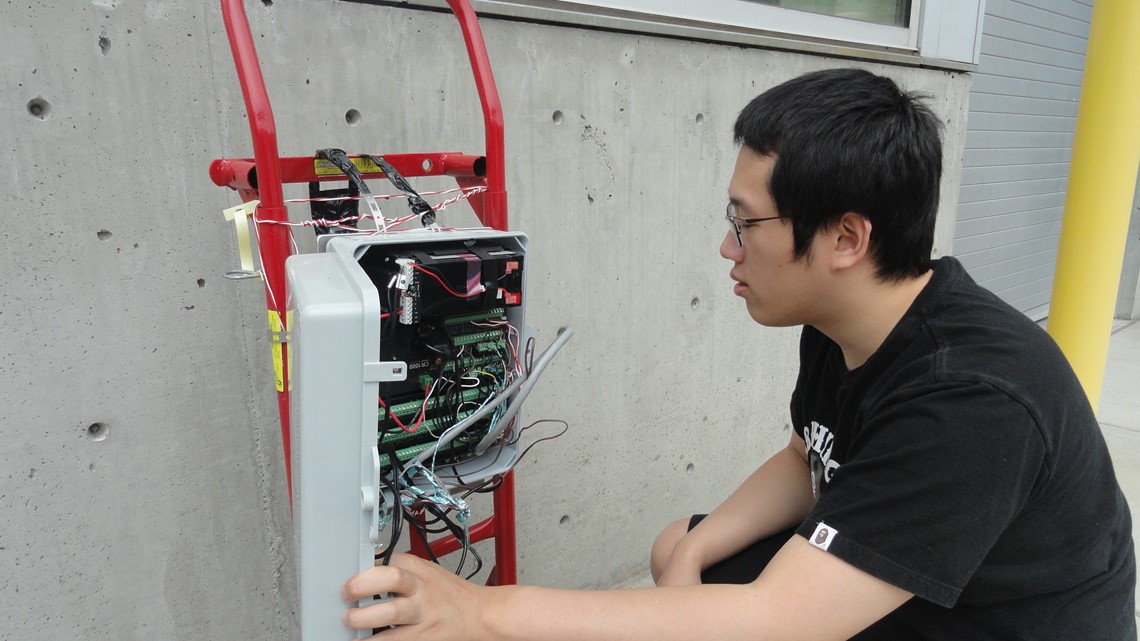

A couple of Washington State University researchers have stepped in to find a solution to this problem. Xianming Shi, associate professor in WSU's Department of Civil and Environmental Engineering, and graduate student Gang Xu, have figured out how to use fly ash in the production of concrete.

The durable new concrete eliminates the use of cement, which is known to be harmful to the environment. Instead of cement, the fly ash is used as a binder in the concrete. By doing this, Shi and Xu are able to tackle two environmental issues with one solution.

Traditionally, concrete is processed by mixing cement with sand and gravel, which contributes anywhere from five to eight percent of greenhouse gas emissions worldwide. Cement is the key ingredient in concrete and to produce it requires extremely high temperatures and a massive amount of energy.

Some researchers have attempted to use fly ash in concrete production but haven't been able to eliminate the intense heating step involved in creating cement.

"Our production method does not require heating or the use of any cement," said Xu.

This new development comes at a time when researchers around the world are beginning to look at engineering on a nano-sized scale, like researching concrete at the molecular level.

"To sustainably advance the construction industry, we need to utilize the 'bottom-up' capability of nanomaterials," said Shi.

In order to activate the fly and turn it into a cement-like material capable of binding the concrete, the team used graphene oxide, a recently discovered nanomaterial, and combined it with the fly ash and water. The combination creates a chemical reaction which rearranges the atoms in the solution, creating strongly bonded atoms in a durable, cement-like binder.

Shi and Xu designed the fly ash concrete to be pervious, meaning that water is able to pass through it. This has the benefit of replenishing groundwater as well as lower potential for flooding.

Several tests at the WSU campus have shown that the new concrete can withstand various kinds of weight loads and temperatures. Other tests, like monitoring sensors buried under the concrete, are still underway.

The researchers hope to one day commercialize the patented technology. Their work on the new concrete was recently featured in the August issue of Fuel, an energy science journal.

"After further testing, we would like to build some structures with this concrete to serve as a proof of concept," said Xu.

The research was funded by the U.S. Department of Transportation's University Transportation Centers and the WSU Office of Commercialization.